Stress

The internal forces and moments generally vary from point to point. Obtaining this distribution is of primary importance in mechanics of materials. The total force in a cross-section, divided by the cross-sectional area, is the stress. We use stress to normalize forces with respect to the size of the geometry.

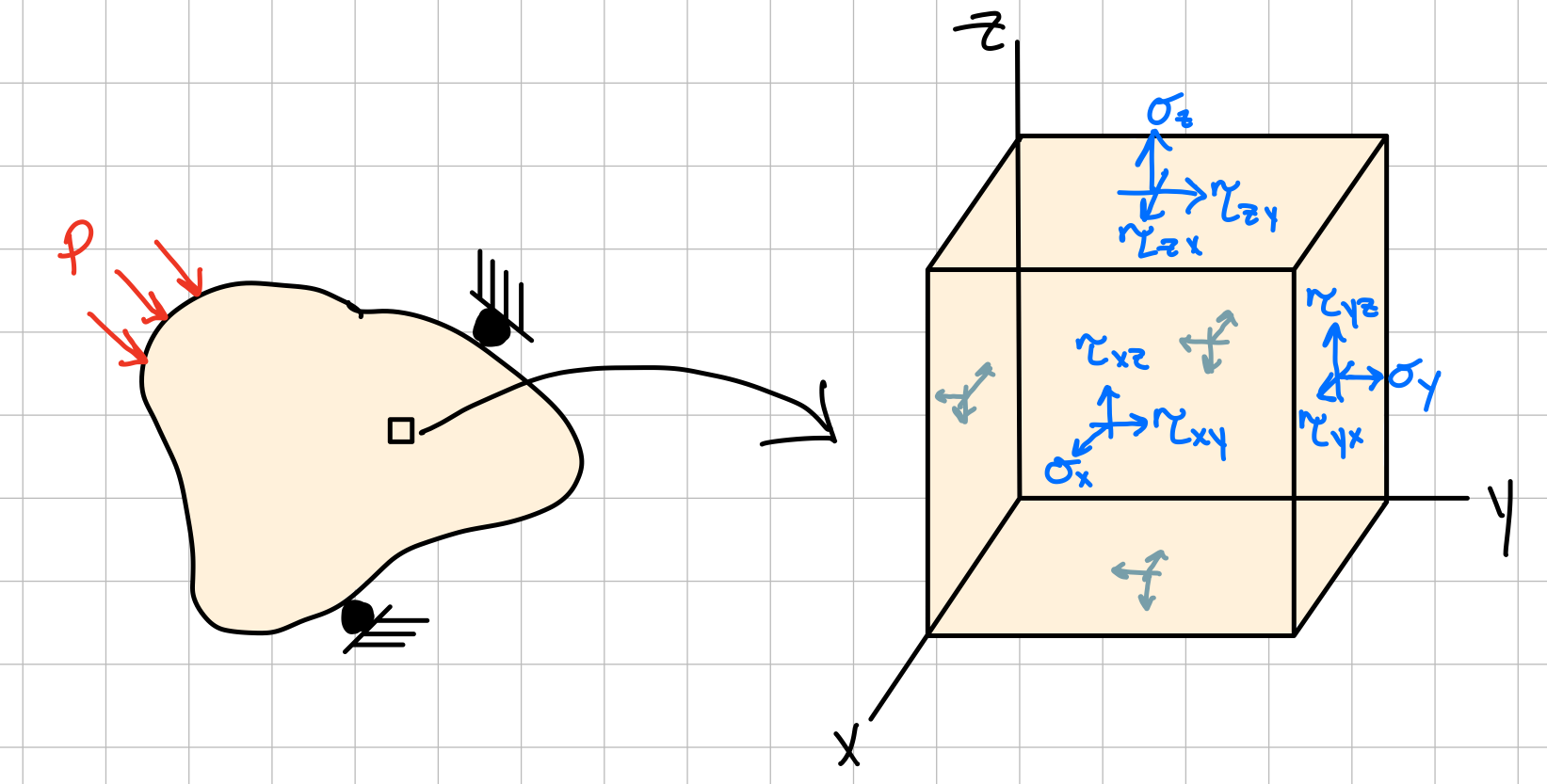

General stress tensor.

Stress under general loading conditions

We consider a homogeneous distribution of the internal force \( \Delta F \) over an infinitesimal area \( \Delta A \). The stress is defined by the infinitesimal force divided by the infinitesimal area.- Normal Stress: Defined by the intensity of the force acting NORMAL to \( \Delta A \)

- Shear Stress: Defined by the intensity of the force acting TANGENT to \( \Delta A \)

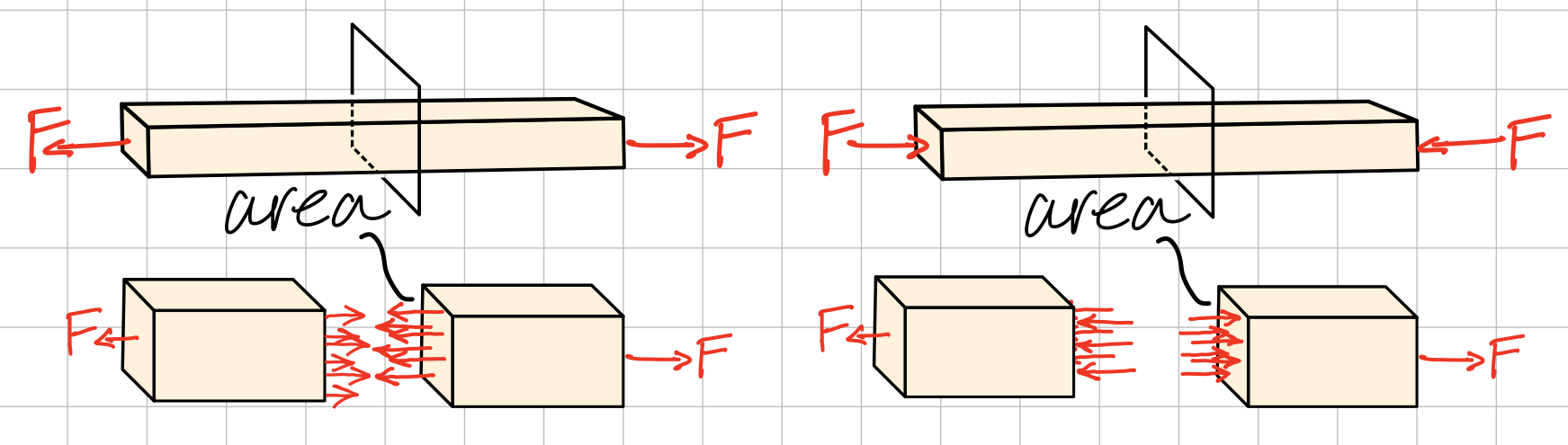

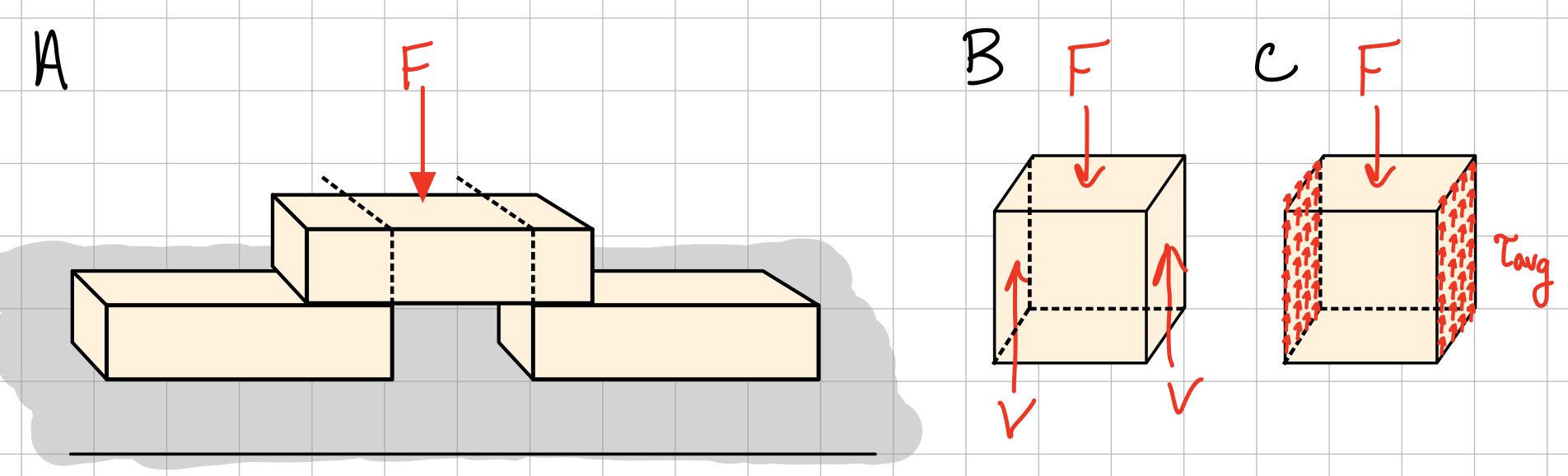

Average Normal Stress - Axial Loading

The normal stress components are represented by the values along the diagonal of the stress tensor. Normal stress tensor.

Normal stress

Average normal stress. #avn-sts

.jpg)

Notation

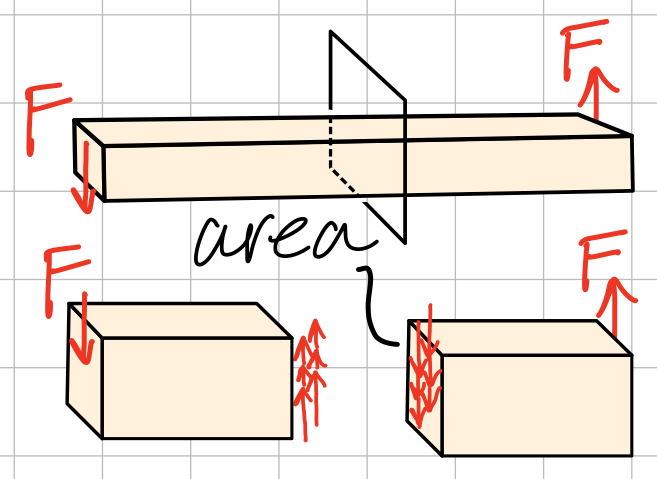

Average Shear Stress

The shear stress components make up the rest of the tensor, consisting of all the components other than the ones on the diagonal. Shear stress tensor.

Shear stress

Average shear stress

Average shear stress. #avs-sts

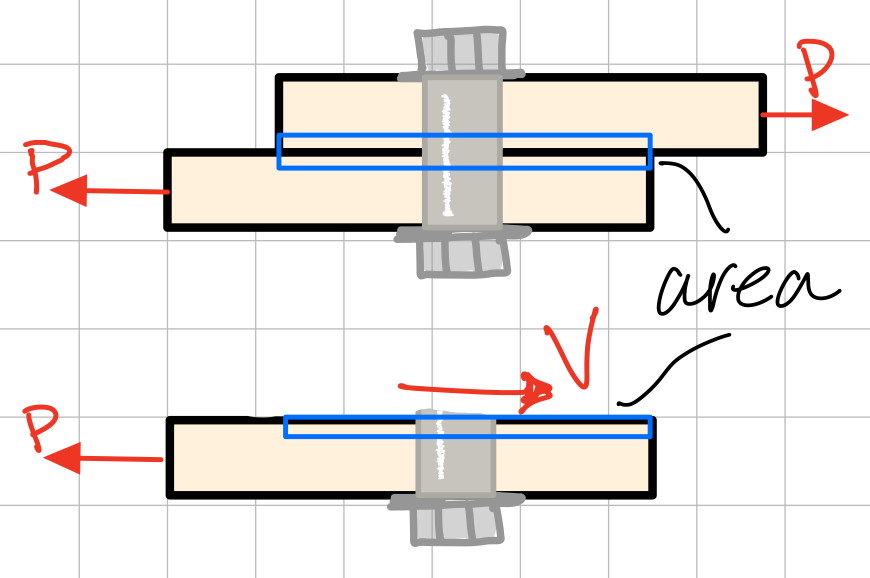

Example Problem: Single shear: determine the shear stress in the bolt #sgl-shr

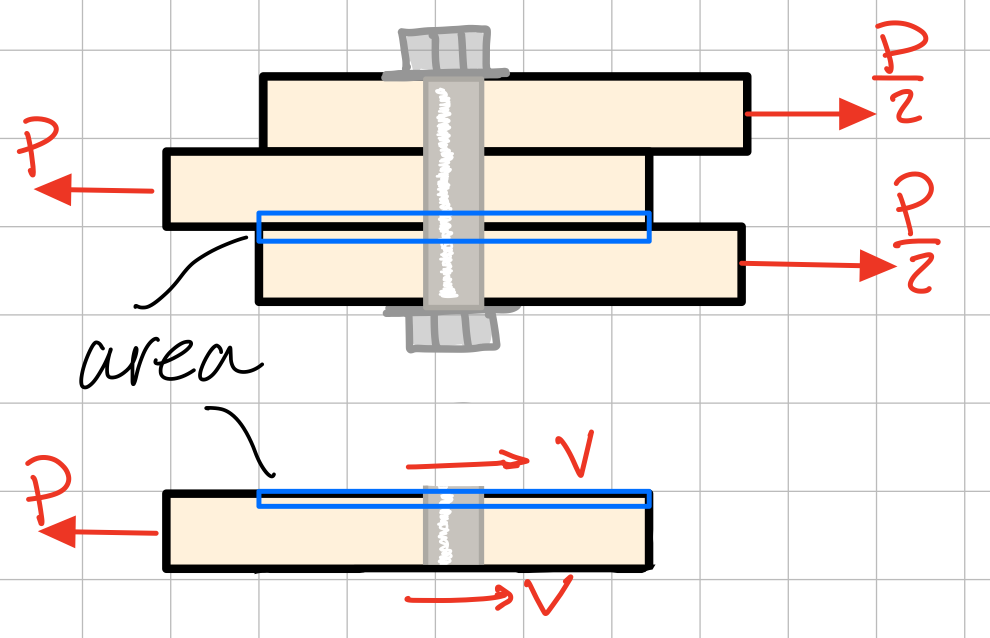

Example Problem: Double shear: determine the shear stress in the bolt #dbl-shr

Extra!

Supplemental video:

General State of Stress

The general state of stress at a point is characterized by three independent normal stress components and three independent shear stress components, and is represented by the stress tensor. The combination of the state of stress for every point in the domain is called the stress field.

Stress tensor.

- Three normal stress components: \( \sigma_x, \sigma_y, \sigma_z \)

- Six shear stress components: \( \tau_{xy} =\tau_{yx}, \tau_{xz}=\tau_{zx}, \tau_{yz}=\tau_{zy} \)

Warning: Stress is a physical quantity and as such, it is independent of the chosen coordinate system. #str-ind

Heads up!

Stress tensor builds on this content later in the course.

Learn more about this topic on the Stress Transformation page.