Material Properties

Continuum Mechanics Fundamentals

Generally, the state of stress a 3D material can be represented as a second-rank tensor (i.e. a matrix) with \( 3^2 = 9 \) components.

Using indicial notation, component \( (i, j) \) of this tensor is denoted as \( \sigma_{ij} \). When \( i \) and \( j \) are not equal, \( \sigma_{ij} \) is commonly denoted as \( \tau_{ij} \) outside of tensor form. Indicial notation can also be used for a material strain tensor.

Using indicial notation, component \( (k, l) \) of this tensor is denoted as \( \varepsilon_{kl} \). Similarly to the stress tensor, when \( i \) and \( j \) are not equal and not using tensor form, \( \varepsilon_{ij} \) is often written as \( \frac{1}{2}\tau_{ij} \). Note that both the stress and strain tensors are symmetric, that is \( \sigma_{ij} = \sigma_{ji} \) and \( \varepsilon_{kl} = \varepsilon_{lk} \).

For our purposes, lets bound the discussion of material stress-strain behavior to only the elastic range, that is, deformation is linear proportional applied load. This is Hooke’s law. The relationship between stress and strain is referred to as the constitutive relationship of a material. In the most general case, this relationship is defined as a fourth-rank tensor with \( 3^4=81 \) components. This elasticity tensor, C, relating the stress and strain tensors is shown in indicial notation (rather than a matrix operation).

What this means is there can be as many as 9 components of strain and 9 material coefficients that contribute to each stress component. (You can see the benefit of indicial notation here.)

However, not all 81 components of this tensor are independent, because of symmetry of stress and strain tensors there are only 21 independent components. If the material is assumed to be isotropic (having the same behavior in all directions) this is further reduced to just 2 independent components (for instance, \( E \) Young’s modulus and \( \nu \), Poisson’s ratio). With this simplification, the 3D isotropic elastic material constitutive relation can be simplified.

Extra!

If you want more details on this topic, consider taking a course in continuum mechanics.

Notation Note

Bold symbols, such as \( \boldsymbol{\sigma} \) and \( \boldsymbol{\varepsilon} \), represent tensors rather than scalar quantities.

Additionally, some quantities might be represented with indicial notation. When indices on the right hand side of the equation are repeated, this represents a summation where the index values range from 1 to 3. For example,

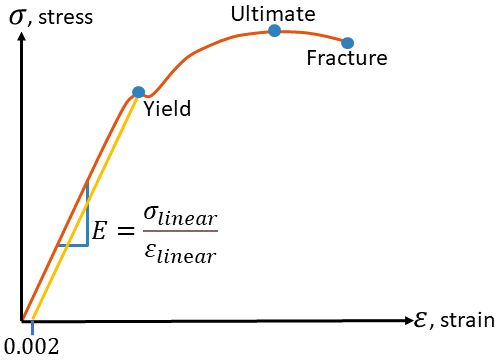

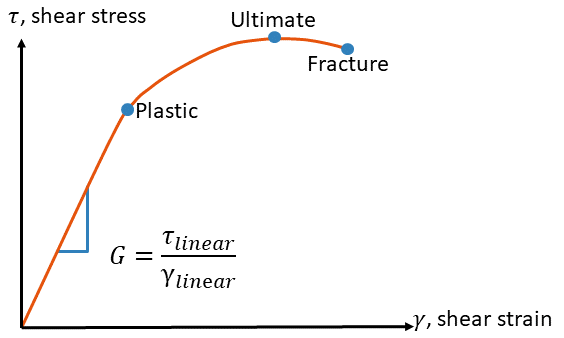

Stress-Strain Diagram

A stress-strain diagram is the relationship of normal stress as a function of normal strain. One way to collect these measurement is a uniaxial tension test in which a specimen at a very slow, constant rate (quasi-static). A load \( P \) and distance \( L \) are measured at frequent intervals.

Elastic Behavior

Loading in this region results elastic behavior, meaning the material returns to its original shape when unloaded. This region of the diagram is mostly a straight line, limited by the proportional limit). This region ends at \( \sigma_Y \) (yielding). For \( \sigma \le \sigma_{pl} \), the diagram is linear, and the behavior is elastic. For \( \sigma_{pl} < \sigma < \sigma_Y \), the diagram is nonlinear, but the behavior is still elastic. Young's Modulus Hooke's law is used for small deformations in the elastic region. The Young's modulus is the slope \( E \).| Material | Young's modulus [\(GPa\)] |

|---|---|

| Mild Steel | 210 |

| Copper | 120 |

| Bone | 18 |

| Plastic | 2 |

| Rubber | 0.02 |

Plastic Behavior

Stresses above the plastic limit (\( \sigma_Y < \sigma \)) cause the material to permanently deform.Yield Strength

Perfect plastic or ideal plastic: well-defined \( \sigma_Y \), stress plateau up to failure. Some materials (e.g. mild steel) have two yield points (stress plateau at \( \sigma_{YL} \)). Most ductile metals do not have a stress plateau; yield strength \( \sigma_{YS} \) is then defined by the 0.002 (0.2%) offset method.

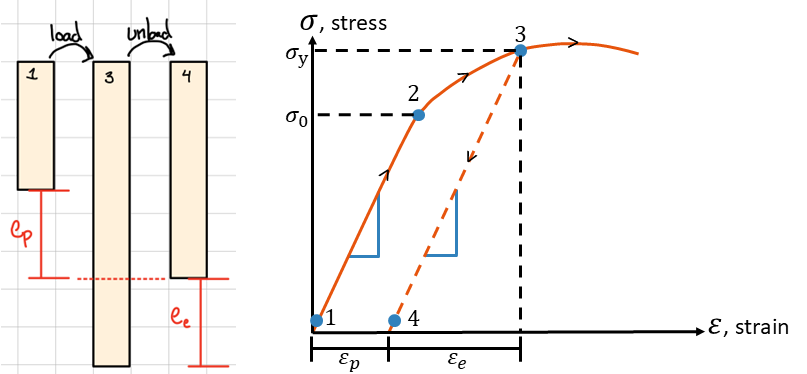

Strain Hardening

Atoms rearrange in plastic region of ductile materials when a higher stress is sustained. Plastic strain remains after unloading as permanent set, resulting in permanent deformation. Reloading is linear elastic up to the new, higher yield stress (at A') and a reduced ductility.

Ultimate StrengthThe ultimate strength (\( \sigma_u \)) is the maximum stress the material can withstand.

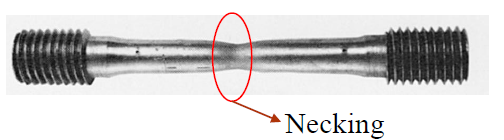

Necking

After ultimate stress (\( \sigma_u < \sigma \)), the middle of the material elongates before failure.

Failure

Also called fracture or rupture stress (\( \sigma_f \)) is the stress at the point of failure for the material. Brittle and Ductile materials fail differently.

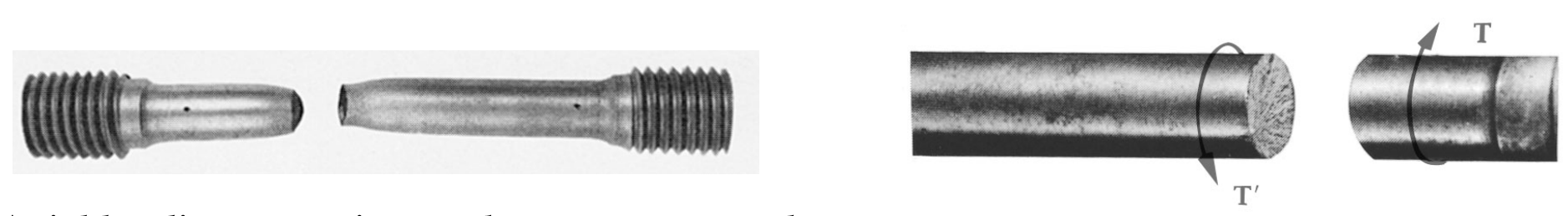

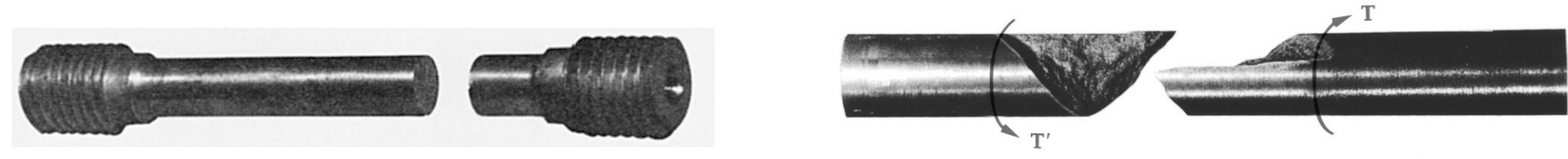

Ductile materials generally fail in shear. There is a large region of plastic deformation before failure (fracture) at higher strain and necking.

Brittle materials are weaker in tension than shear. There is a small plastic region between yield and failure (fracture) and no necking.

Note the difference between engineering and true stress/strain diagrams: ultimate stress is a consequence of necking, and the true maximum is the true fracture stress.

Example: Concrete is a brittle material.- Maximum compressive strength is substantially larger than the maximum tensile strength.

- For this reason, concrete is almost always reinforced with steel bars or rods whenever it is designed to support tensile loads.

Heads up!

Strain Energy builds on this content in Engineering Materials.

Deformation does work on the material: equal to internal strain energy (by energy conservation).

Heads up!

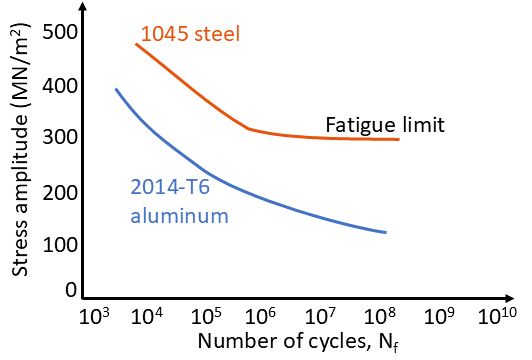

Fatigue builds on this content in Engineering Materials and Mechanical Design.

Directional Materials

- Isotropic: material properties are independent of the direction

- Anisotropic: material properties depend on the direction (ie; composites, wood, and tissues)

Poisson's Ratio

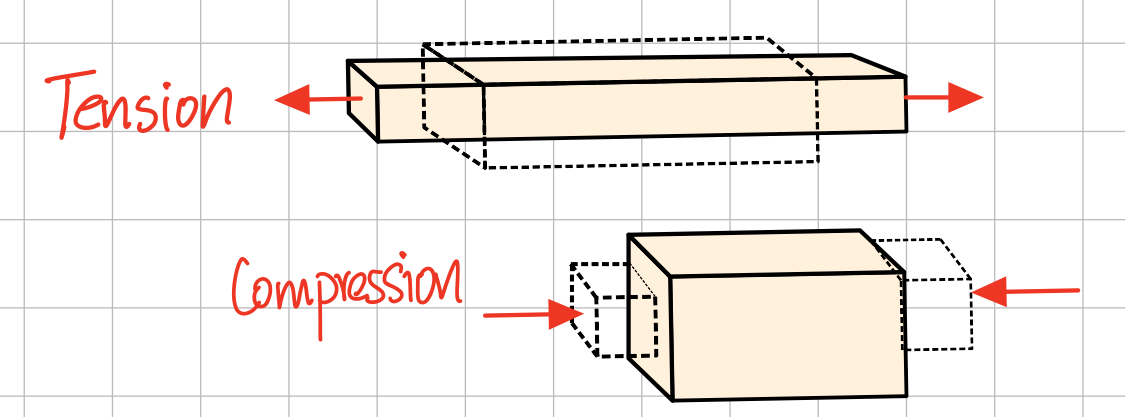

As illustrated in the figure above, when an object is being compressed it expands outward, and when stretched it will become thinner. Depending on the material, it may experience more or less lateral deformation for a given amount of axial deformation. The ratio that governs the amount of lateral strain per unit of axial strain is called Poisson's ratio.