Bending

Transverse loads applied to a horizontal straight beam will cause it to deflect primarily up or down. This type of deformation is referred to as bending. A beam in bending will develop normal (tensile and compressive) bending stresses throughout the beam. The magnitude of these stresses depends on the internal bending moment in the beam as well as the beam's cross-section geometry.Pure Bending Tensor

For pure bending loading conditions, the stress tensor can be simplified as shown below, depending on whether bending occurs around the y or z axis.

Bending stress tensor. #ben-tsr

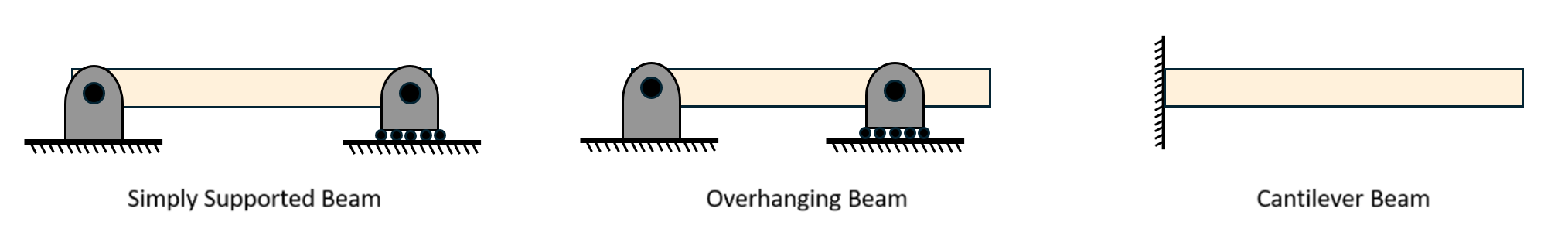

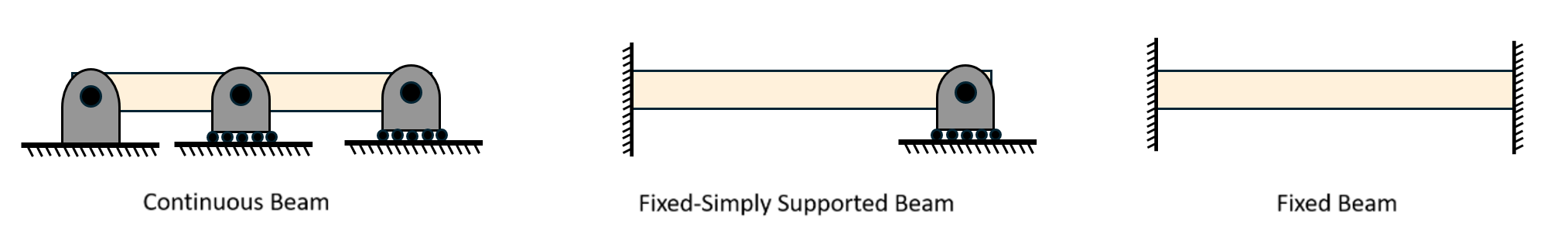

Boundary Conditions

Below are common support conditions and loading conditions that are used to model beams.

Pin supports allow rotation but not translation; fixed supports restrain both translation and rotation of the beam at that location.

Statically Determinate Beams

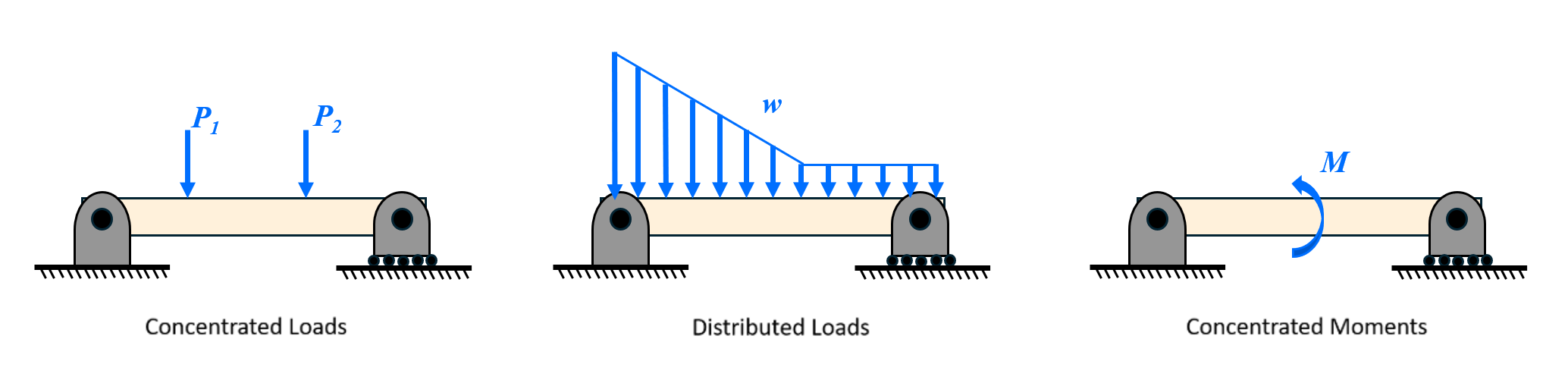

Pure Bending

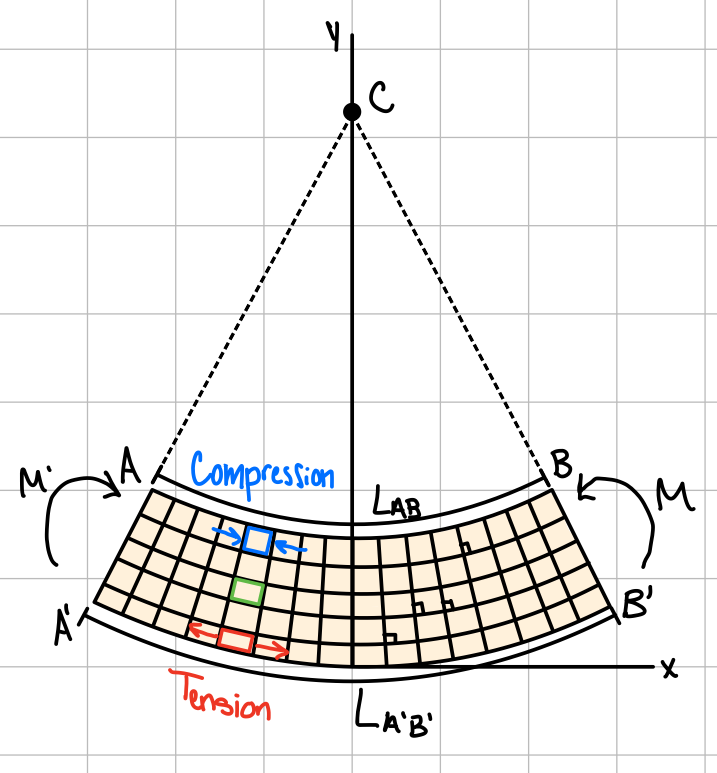

Geometry of Deformation

Bending diagram

-

Plane sections remain plane \( \rightarrow \)no shear stress/strains.

Therefore:Also, traction free boundary conditions yields...

-

There is a Neutral axis between the top and the bottom where the length does not change.

-

The beam deforms into a circular arc where the top surface (\( AB \)) is in compression , and the bottom surface (\( AB ^\prime \)) is in tension.

- Any point in the beam is in a state of uniaxial normal stress.

- Finding stresses is a statically indeterminate problem.

Stress-Strain Variations

Material Behavior: linear elastic beams

Elastic range: bending moment is such that the normal stresses remain below the yield strength. Hooke’s law combined with equilibrium.

Moment-curvature equation. #mmt-crv

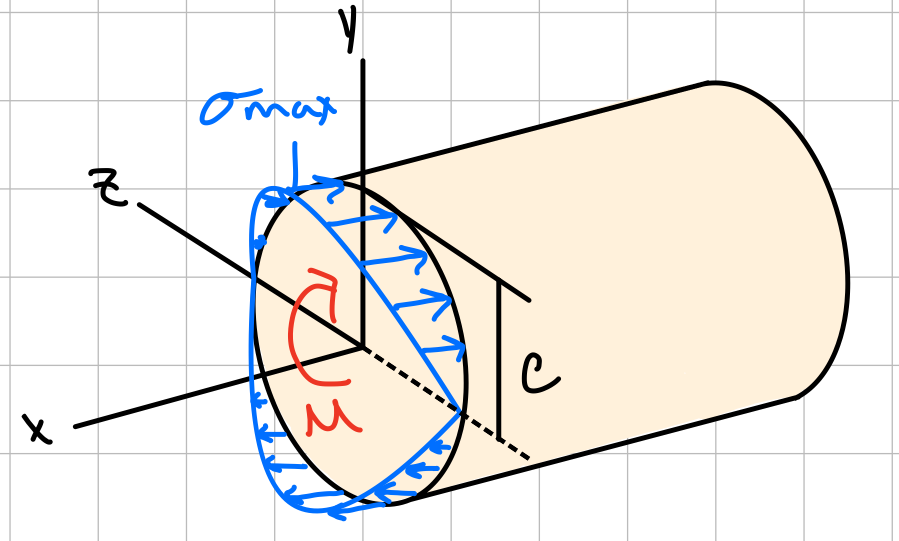

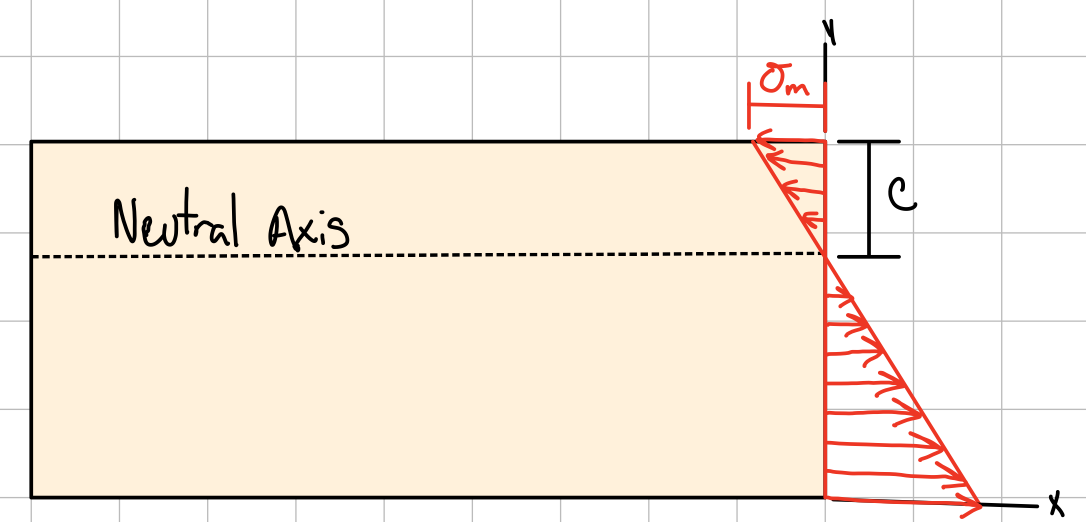

Maximum Normal Stress

From equilibrium: the centroid is located at \( \bar{y}=0 \), i.e., the neutral axis passes through the centroid of the section. Elastic flextural formula. #ela-flx

Absolute maximum stress.

Absolute maximum stress.

Elastic section modulus.

Heads up! - Extra

Composite beams builds on this content.

Recall that \( \epsilon_x = -\frac{y}{\rho} \) does not depend on the material properties of the beam, and is based only on the assumptions of geometry done so far.

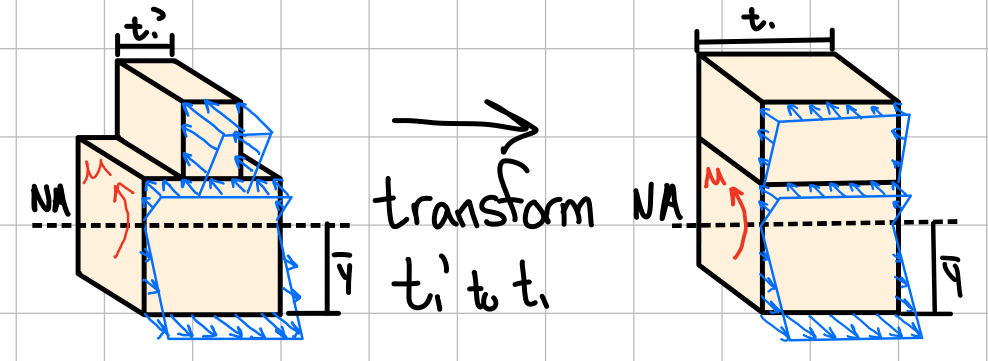

After obtaining the TRANSFORMED CROSS SECTION, we get

Note: the widening (\( n > 1 \)) or narrowing (\( n < 1 \)) must be done in a direction parallel to the neutral axis of the section, since we want y-distances to be the same in the original and transformed section, so that the distance y in the flexural formula is unaltered.

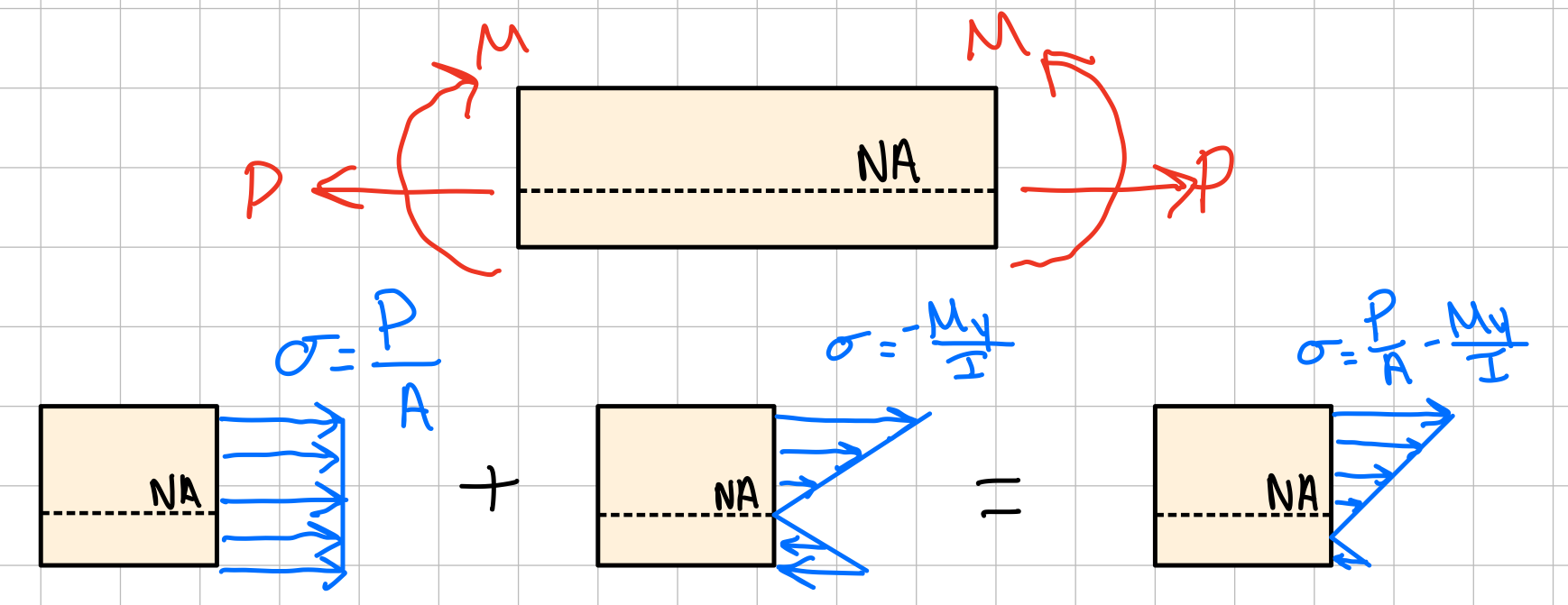

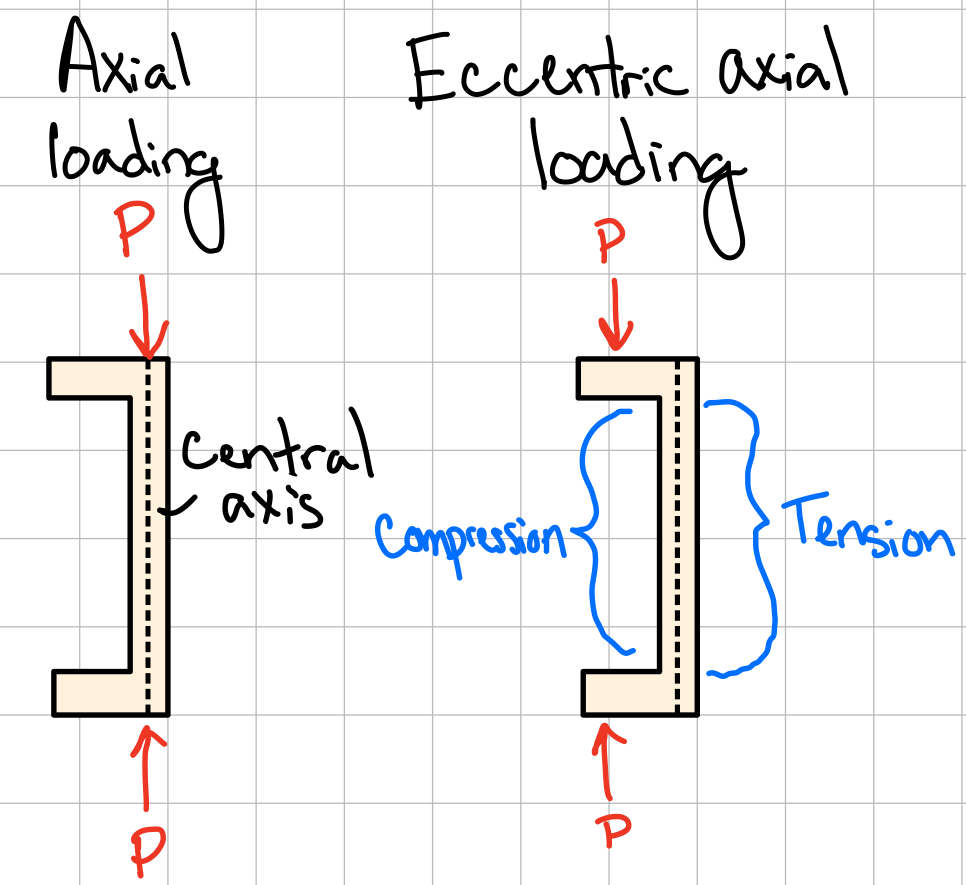

Eccentric Axial Loading in a Plane of Symmetry

Equilibrium.